Ojales

Notin a reputable manufacturer in China, is willing to offer you Eyelets. We promise to provide you with the best after-sale support and prompt delivery.

Eyelets are characterized by quick installation, stable performance, and high reliability. Compared to other fasteners, eyelets are significantly cheaper per unit and have a wide range of applications. They are similar with tubular rivets, but made from different technics and machines.Eyelets are made from deep drawn technics, and tubular rivets are made from tube.

What is an eyelet?

An eyelet primarily consists of a cap and a shank. The cap is typically round or oval, offering a large surface area for easy hammering during installation. The shank is of moderate length and diameter, ensuring the rivet securely connects two or more components. The primary function of this type of eyelet is to connect and secure components, ensuring a secure connection without damaging the material.

What types of eyelets are there?

Based on the material used, they can be categorized as brass eyelets, steel eyelets, stainless steel eyelets, aluminum eyelets, and copper eyelets. Different eyelets have different characteristics depending on their material properties.

Brass eyelets: They offer excellent electrical conductivity and corrosion resistance, making them widely used in various electrical connections and fastening applications.

Steel eyelets: steel offers high strength and hardness, and are relatively inexpensive. However, steel has poor corrosion resistance and is prone to rusting, especially in humid environments. Therefore, the application range of iron eyelet rivets is relatively limited.

Stainless steel eyelets: Characterized by their strong corrosion resistance, they are often used for fastening food-grade products. However, due to the material's relatively high hardness, production is challenging, resulting in a relatively high unit price.

Aluminum eyelets: Used for fastening shoelace holes, belt holes, and windbreaker drawstrings, they allow for quick donning and doffing, while enhancing aesthetics.

Copper eyelets: Due to their excellent electrical conductivity, they are often used for connecting and securing electronic products.

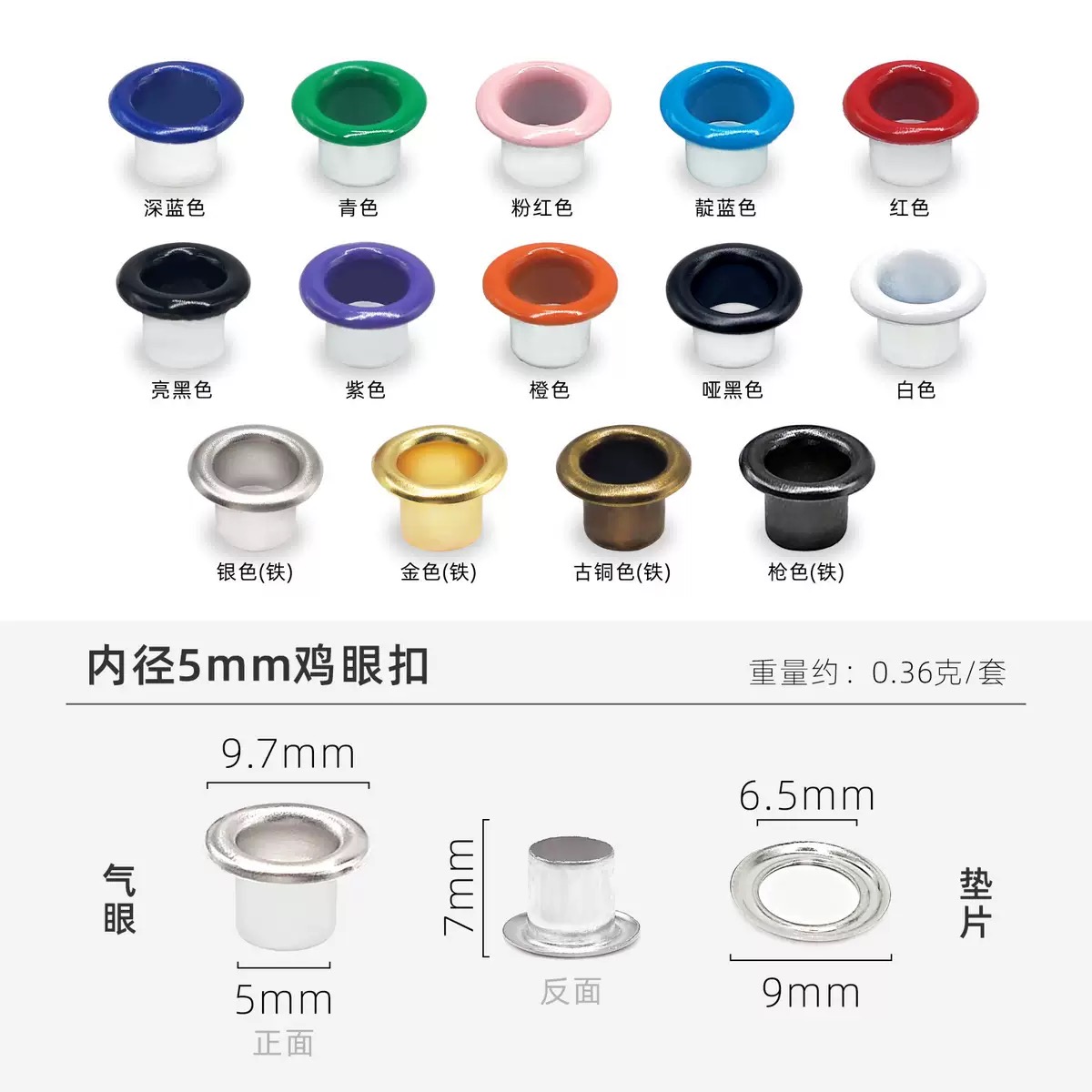

What surface treatments are available for eyelets?

Eyelets are hot-dip galvanized and polished to create a protective layer on the surface that provides antistatic, corrosion-resistant, and anti-allergenic properties. Copper eyelets come in a variety of colors, including white nickel, polished tin, imitation gold, antique bronze, matte nickel, bronze, zinc, and silver.

Some customers also prefer to have the eyelet head powder coating to match their color with the overall design and prevent oxidation.

- View as

Ojales de aluminio

Aquí, en nuestra fábrica de Dongguan, Nuote Metals produce ojales de aluminio de calidad. Llevamos muchos años centrándonos en la fabricación de ojales de aluminio. Nuestro aluminio se selecciona cuidadosamente para que sea ligero y resistente. Estos ojales de aluminio no se oxidan y mantienen su acabado brillante. Ofrecemos ojales de aluminio en varios tamaños. Algunas son diminutas, otras bastante grandes. Cada ojal de aluminio es examinado por nuestro personal. Comprueban la forma y la superficie. Los clientes suelen elegir nuestros ojales de aluminio. Los encuentran confiables y atractivos. Ofrecemos muestras rápidas para aquellos que quieran probarlas.

Leer másEnviar ConsultaOjales para PCB

Un ojal de PCB es un pequeño anillo de metal diseñado para instalarse en una placa de circuito. Puede parecer simple, pero juega un papel importante. La gente los usa para crear agujeros fuertes y confiables en una PCB. Este pequeño componente ayuda a garantizar que las conexiones no se dañen durante el montaje o el uso. Nuote Metals estará encantado de ayudarle a saber más sobre los ojales para PCB.

Leer másEnviar ConsultaOjal metálico

Somos Nuote Metals de Dongguan, China. Nuestra fábrica fabrica muchos tipos de ojales metálicos para diferentes usos. Hemos fabricado productos con ojales metálicos durante más de diez años. Utilizamos diferentes metales para fabricar estos artículos con ojales metálicos. El latón, el acero y el aluminio son materiales comunes. Fabricamos ojales metálicos en todos los tamaños. Los pequeños para zapatos, los grandes para lonas. Nuestros trabajadores revisan cada ojal metálico antes de empacar. Prueban cada pieza para asegurarse de que funcione bien. Muchos clientes compran nuestros productos de ojales metálicos con regularidad. Les gusta nuestra buena calidad y suministro confiable.

Leer másEnviar ConsultaOjales para zapatos

Fabricamos ojales para zapatos en nuestra fábrica en Dongguan, China. Los ojales son pequeños anillos de metal que se pueden ver en los zapatos para los cordones. También se les llama ojales. Los hacemos fuertes para que no se rompan cuando aprietas los cordones. Nuestros ojales para zapatos están hechos de diferentes metales, como latón, aluminio y acero inoxidable. Y se pueden hacer con diferentes colores para combinar con todo tipo de zapatos.

Leer másEnviar ConsultaRemache de ojal

Un remache con ojal es un cierre pequeño pero útil. Tiene forma de tubo corto y suele estar hecho de latón o acero. Cuando se instala, la cola del remache se ensancha para unir los materiales de forma segura. Muchas empresas de todo el mundo producen estos componentes fiables. Nuote Metals, con sede en Dongguan, China, es un conocido fabricante de remaches con ojales de calidad.

Leer másEnviar ConsultaOjales para cortinas

Producimos una amplia variedad de ojales para cortinas en Nuote Metals en Dongguan, China. Estos ojales son los anillos de metal que se ven a menudo en la parte superior de las cortinas modernas. Fabricamos estos ojales para cortinas en diferentes tamaños y acabados, como níquel y negro, para adaptarse a varios estilos. Nuestro trabajo es garantizar que cada anillo sea suave y duradero, listo para usar en hogares y oficinas.

Leer másEnviar ConsultaWhat are the main applications for eyelets?

Eyelet rivets are widely used in the construction, automotive, marine, aviation, and electronics industries.

In the construction industry, eyelet rivets are used to connect various metal components, such as steel beams and columns.

In the automotive, marine, and aviation industries, eyelet rivets are used to connect various materials, such as aluminum alloys and titanium alloys.

In the electronics industry, eyelet rivets are used to connect various metal and non-metallic materials, such as metal plates and plastic sheets.

What tools are used to rivet eyelets?

Eyelet rivets can be riveted using either manual or electric riveting pliers. Manual riveting pliers are a common tool and are generally suitable for riveting small eyelets. Electric riveting pliers are suitable for riveting large eyelets and large quantities.

What preparations are required before riveting?

Preparation before riveting includes cleaning the surface of the material being riveted and selecting the appropriate rivet hole diameter. Cleaning the surface of the material being riveted removes surface dirt and grease, ensuring a secure joint. Selecting the appropriate rivet hole diameter can prevent cracking or loosening during riveting.

What precautions should be taken when riveting?

1. The installation position of the eyelet rivet must coincide with the centerline of the rivet hole.

2. The eyelets shank should be perpendicular to the surface of the material being riveted during riveting.

3. The eyelet head must remain horizontally stable.

4. The depth of the eyelet hole should be equal to the sum of the rivet shank length and the length of the eyelet pressure riveting portion.

5. The riveting force should be appropriate, neither too high nor too low, depending on the thickness and properties of the material.

6. After riveting, the eyelets quality should be inspected for signs of broken eyelets or foreign matter.

Conclusion

Eyelet rivets are a versatile rivet fastener that can be widely used to connect various metal sheets and dissimilar materials. Thorough preparation is required before riveting, including selecting the appropriate rivet hole diameter and cleaning the surface of the material being riveted. During riveting, factors such as the riveting force and hole depth should be carefully considered to ensure a high-quality connection.